Quality assurance enables you to detect defective products or products that do not meet the quality standards you require. Thus a constantly high quality of your products can be guaranteed. For the quality assurance of your products, we offer individual testing stations adapted to your needs.

Our manual inspection stations enable the turning of heavy workpieces with the use of aero wheels. This simplifies the visual inspection on the different sides of the component. It reduces the physical strain on the inspector and ensures ergonomic working. The illustrated inspection stations are designed for robot loading and unloading. While the robot removes the inspected workpiece and loads another workpiece to be inspected, the inspection takes place by an operator on the other side.

Semi-automated inspection stations support the inspector with a predefined inspection sequence. A robot positions the workpiece at the areas to be inspected. In addition to improved ergonomics, which can be easily adjusted to the size of the inspector, the probability of errors is reduced by the predefined inspection sequence. It is also possible to incorporate the results of previous quality controls. For example, if a defect is known in a certain area, it can be explicitly presented to the inspector. Semi-automated test stations reduce the duration of the test procedure and ensure that test sequences are adhered to.

Our leak test systems detect possible leaks and thus check the tightness of your workpiece. The leak test is used, among other things, for cylinder heads and motor blocks. The systems can be operated manually or fully automatically.

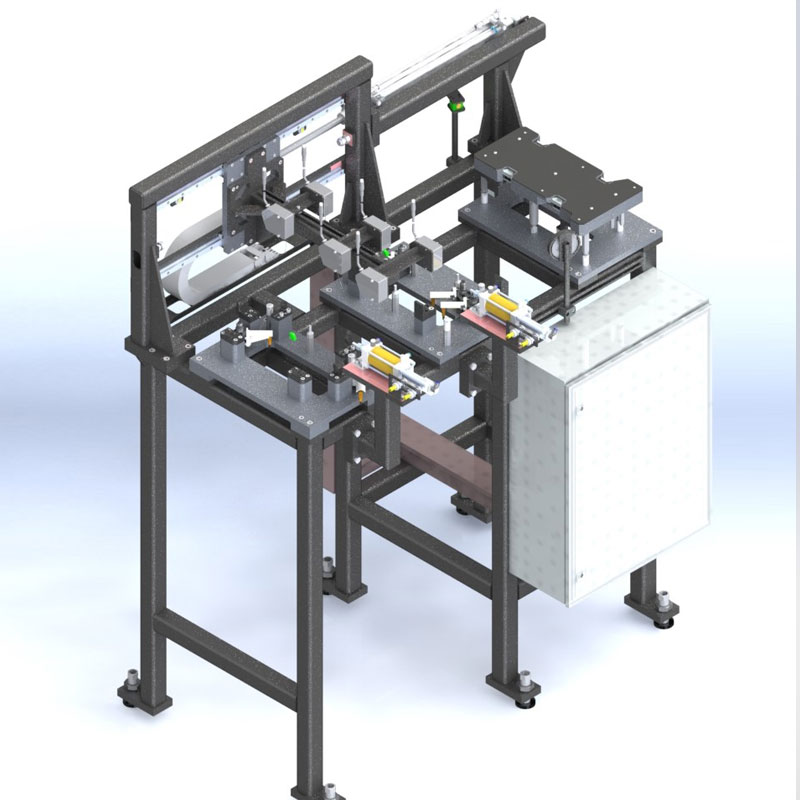

Tactile measuring stations provide highly precise measuring results for highly reflective measuring surfaces or surfaces with changes in colour. We use digital probes for our measuring stations. These can also be used in a rough and oil contaminated environment. Based on your measuring task, we develop the entire test station for you with component-specific devices and the necessary automation technology. The measurement results are evaluated and visualised. Depending on customer requirements, the results can be transferred to higher-level control systems or to the cloud. Storage at the test station with the associated test protocol is also possible.

Laser measuring stations are advantageous for measuring tasks that require a certain distance or a large number of measuring points, for example with a line profile. Furthermore, no moving mechanical components are required. For your individual testing task we develop a suitable test station with automatic measured value evaluation. The stations can be integrated into an automated production line or designed as manual test stations.

Laser station for the inspection of sawcuts on castings

At this station a robot moves the workpiece to the measuring position. 20 lasers then measure the height of the cuts. The measurement result is processed in the PLC and transferred to the control system.

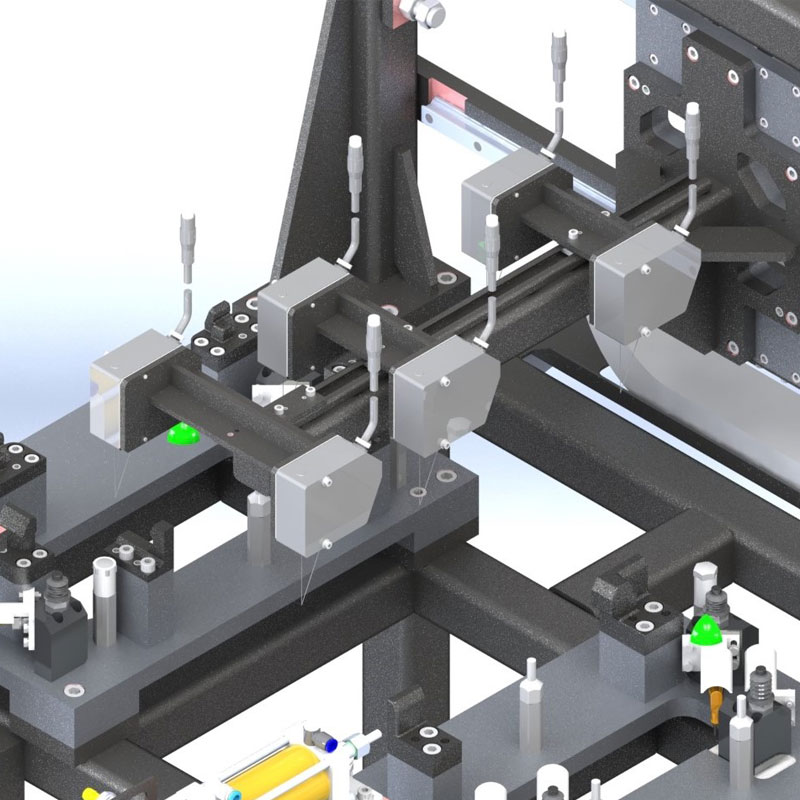

In the following laser measuring station, the robot places the workpiece in a fixture. After depositing, a measuring arm with six laser sensors moves to the measuring position. The measurement result is evaluated in the PLC and documented accordingly. Referencing of the laser measuring station is carried out fully automatically with the use of a calibrator at the station, which is gripped by the robot and placed on the tray to be calibrated. To check the referencing, this may be carried out at various times or after a certain number of measured workpieces.

Temperature tests are used for workpiece and system protection. Some processes may only be carried out up to a certain temperature. Plant components may also wear out or destroy more quickly if workpieces are overheated. This can be avoided by temperature testing stations. The station can be integrated into automated systems.

In the field of image processing we offer various solutions for your component inspection. We develop the complete inspection station and put it into operation. Our image processing stations are integrated into automated systems or designed as stand-alone test stations. Learn more about 2D measuring systems, 2D image processing systems, 3D profile sensors and 3D area cameras in the field of engineering and image processing.

More about Image processing

We automate and integrate X-ray equipment and computer tomographs. We ensure rapid loading and unloading of the inspection stations with the use of robot or handling systems. Based on your workpiece geometry, we develop suitable gripping systems and the entire cell layout. The inspection system may be extended with buffer stations as required. In this way, workpieces are only conveyed out of the cell after successful testing. Manual inspection stations may be integrated at the cell to enable reworking. The reworked part can then be fed back into the cell for a new inspection. It is also possible to integrate a palletizing system. In this way, IO and NIO workpieces are stacked directly at the right position.

Your contact for Quality Assurance