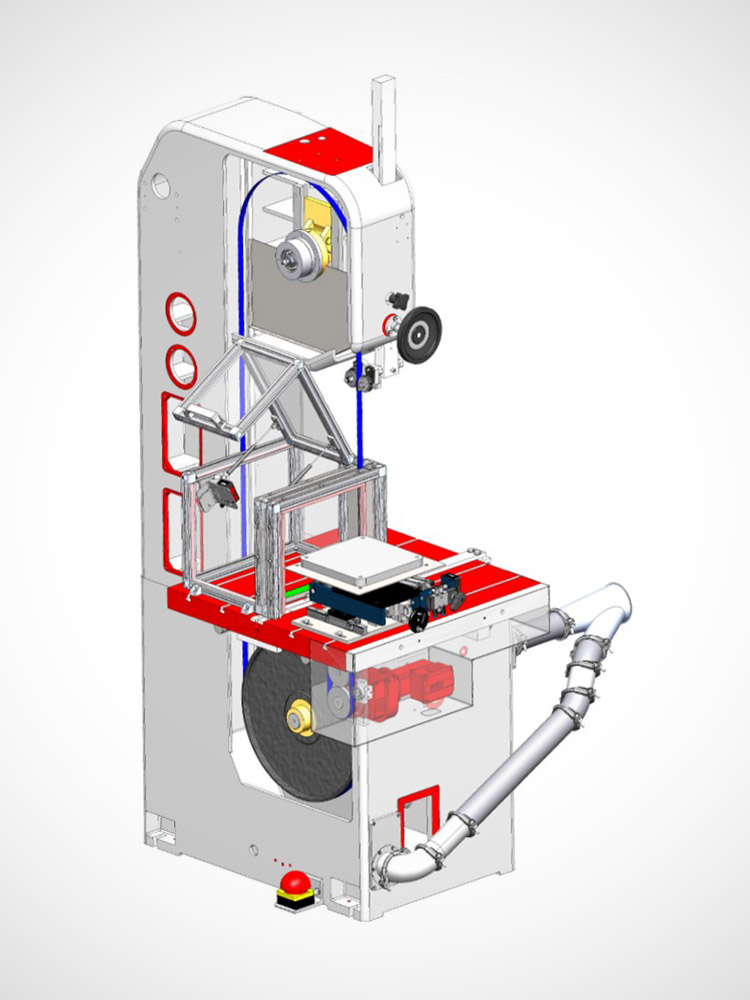

Nowadays, 3D printing has developed into an important manufacturing area for a wide range of applications. Especially for this area, we have added a saw for additive manufacturing to our product range based on our proven SSF 520. The band saw system consists of our proven SSF 520 with feed table and infeed unit. There are 3 different table variants available. This machine is used to remove the support structures on 3D-printed components. Band saw dimensions from 6 mm to 27 mm are possible.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

| Technical specifications |

3D print bandsaw |

|---|---|

| Voltage | 400 Volt/50 Hertz |

| (other voltage against extra cost) | |

| Cutting speed range | 22 – 150 und 338 – 2280 m/min |

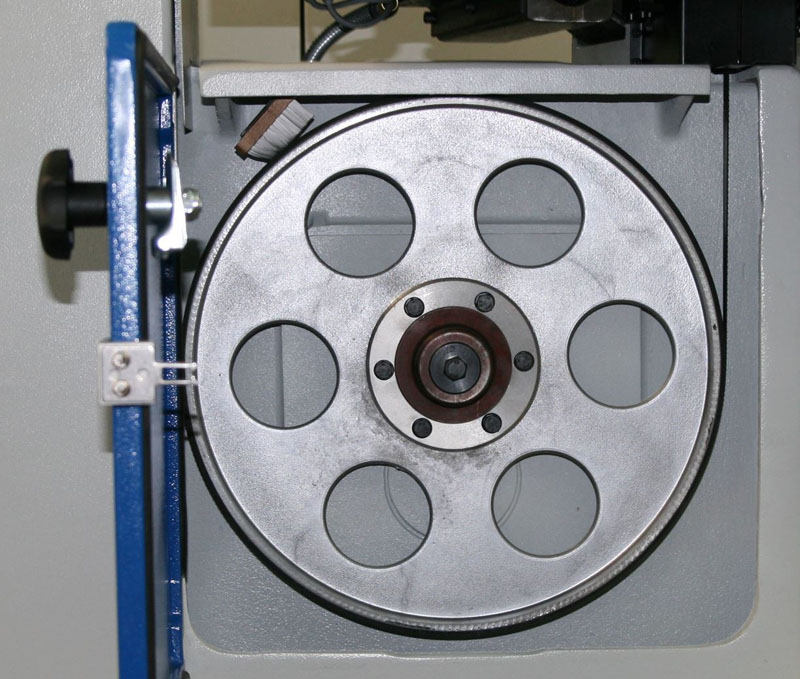

| Wheel diameter | 520 mm |

| Cutting length | 300/600/1000 mm |

| Cutting height | 300/500/500 mm |

| Motor power | 5,5 k/W 400/690/50 Volt/Hertz 1500 × 1/min |

Technical details

Optional equipment bandsaw for 3D prints

Butt welder

Butt welder EBS for sawblades, incl. shear and grinding motor.

Available EBS types:

Electronic annealing function for welding unit

Electronic annealing function for continuous setting of the annealing voltage for convenient treatment of the weld (for voltage until 400 Volt, 50 Hertz)

Special voltages for butt welder

Different voltages can be realised depending on the recipient country.

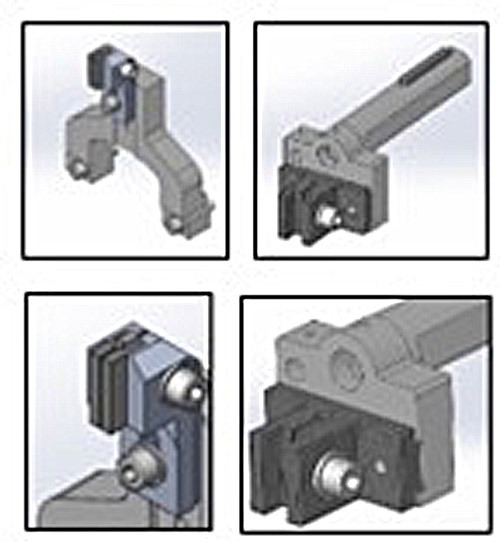

jaw guides with inserts

Bracket jaw guides bottom and top including carbide-tipped guide inserts for bracket jaw guides

Inserts for jaw guides

Carbide-tipped guide inserts for jaw guides

Roller guides

Roller guides inducing guide rollers used for curing speeds starting at 250 m/min.

Guide rollers

1 set = 2 pieces with rim, 2 pieces without rim

Guide dimensions depending on the saw band used

Alignment with laser

For exact positioning a laser beam projects a laser beam on the surface of the workpiece. This beam points out the cutting channel.

Used laser: Helium-neon-laser with a prefixed lineoptic, not dangerous for the eye (corneal reflex).

LED lamp

LED lamp for lighting of the working area.

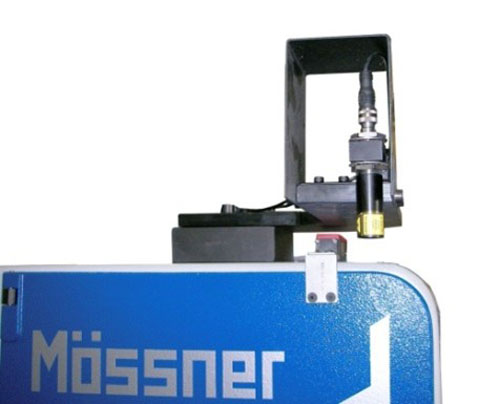

Laser distance sensor

Laser distance sensor for exact alignment of the mounting base plate for cutting the casting.

Stationary suction unit

Stationary suction unit for removal of chips and dust during cutting process.

Wheel

Aluminium wheel with vulcanised hard rubber coating

Credit notes are issued for returned used wheels that are in usable condition

Saw bands

We offer you saw bands in a wide range of designs and for varies application areas whether in

Saw band dimensions from 6 – 27 mm are possible. We will be happy to advise you and together we will find the

suitable saw band for your application.

Your contact for Mössner bandsaws