There is no alternative for the maintenance of your machine. It should be done regularly and professionally. We develop individual service offers for your needs.

Machine availability, precision and service life of your machine or plant depend on regular maintenance. Preventive maintenance contributes significantly to this. Individually adapted maintenance schedules and the resulting measures are a useful way of designing maintenance processes. As a result, unplanned downtimes can be minimized. Unscheduled costs are also reduced, as defects are detected early. This allows a precocious spare parts backup and planning of repairs.

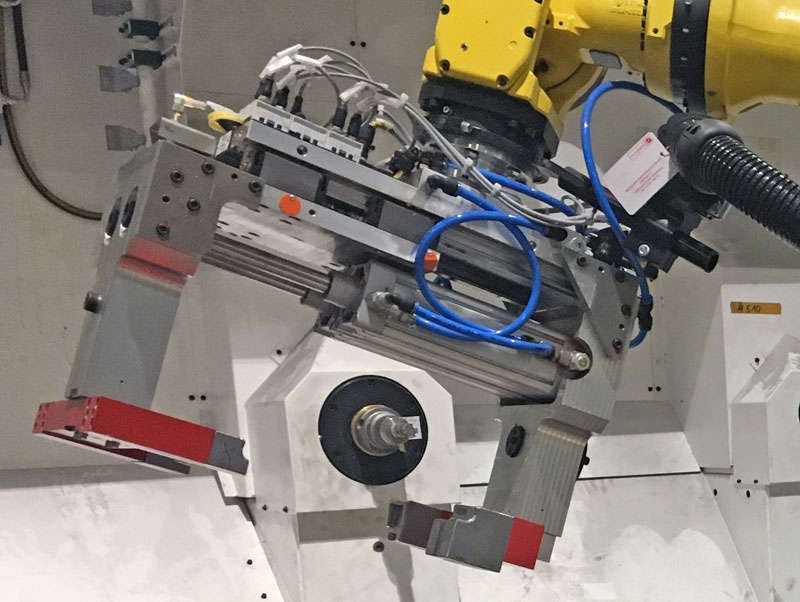

Our experienced employees are at your disposal with competent advice and the latest technologies. We take care of machine inspections, maintenance, repairs and spare parts in order to find an answer to your question or a solution to your problem quickly and easily.

Take advantage of the following benefits by maintenance or machine inspection:

We gladly carry out the maintenance work on your machine, so that your machine continues to serve you in the usual Mössner quality. For special machines, maintenance is carried out by maintenance schedules individually tailored to your machine. For series machines a standardized maintenance plan is used.

In case of deviations from the nominal condition, our experienced service personnel gives advice on how this can be achieved again as quickly, efficiently and cost-effectively as possible. In addition, we would also be pleased to inform you on site about possible improvements to your machine, which are the result of continuous further development of our systems.

Your contact for machine inspections, maintenance, repairs and service