During workpiece processing, chips are produced which enter the casting or adhere due to the used minimum quantity lubrication. In addition, areas may be opened during machining which previously did not allow the sand to be removed. Our cleaning stations take over this task. They work with compressed air, vibrators and pneumatic hammers. Depending on the task, combined vibrator stations with blast air, hammer stations or vibrator stations with rotary drive are available, to reliably remove chips, sand and blasting material.

The following station is suitable for removing blasting material. It is equipped with a rotary drive and unbalanced motors which shake the blasting material out of the part. The cleaning station may be loaded and unloaded by a robot.

The subsequent cleaning station removes adhering sand by means of vibration and compressed air.

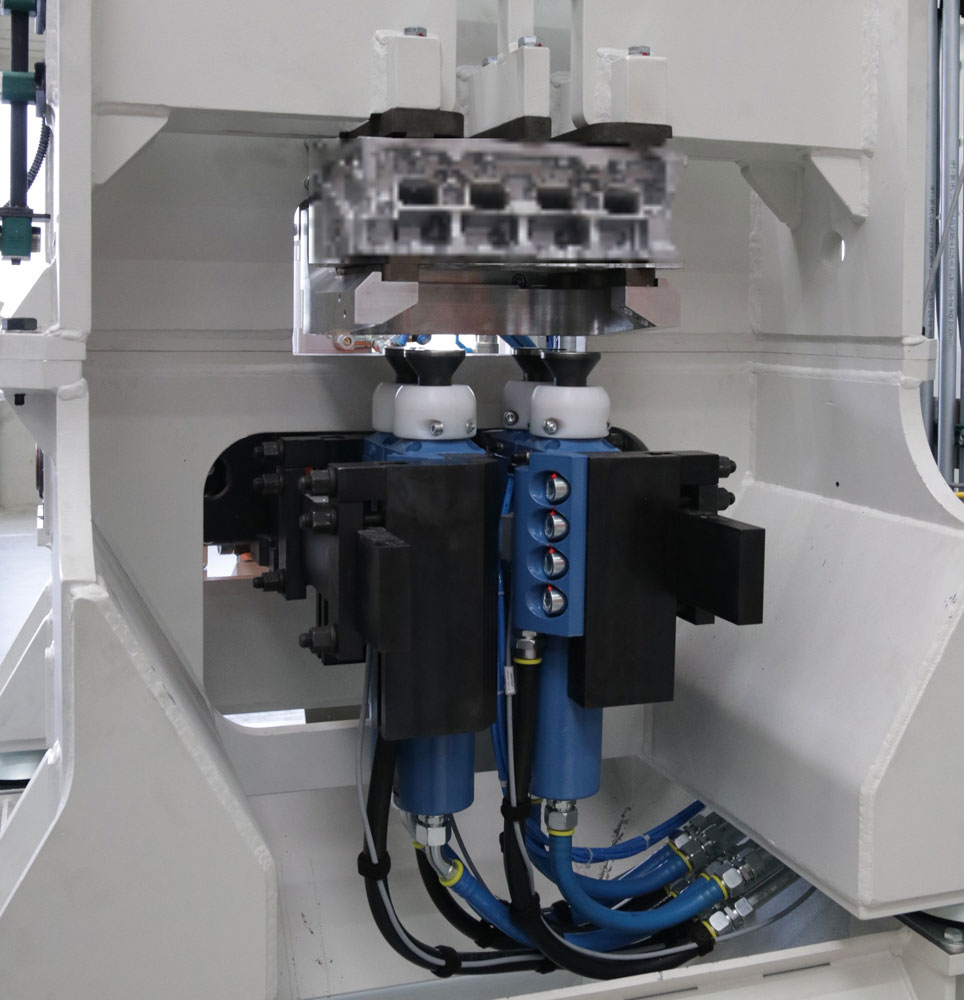

The cleaning station for cylinder crankcases, for example, removes residual sand and chips that have entered the casting during the machining process. It enables blowing out with compressed air, vibration and turning.

The parts can be cleaned using compressed air in the integrated processing and cleaning station. After machining, the robot moves to air nozzles. Here the workpiece is rotated and turned over.

Hammer stations can be used for final sand removal. This is where chip residues and sand accumulate.

Your contact for cleaning