Whether gravity chill casting or tilting chill casting with rotation of the mould by 90 ° or 180 ° – we supply the appropriate systems technology for your casting process. Our casting systems are suitable for a wide range of castings, such as cylinder heads or differential housings. Robots or handling systems take over the insertion of the cores into the gravity and tilting chill casting machines. Once the mould is closed and in its initial position, the melt is introduced. This is done by casting robots using a ladle.

With our tilting chill casting machines, the speed of rotation of the mould can be regulated accordingly. This presents following advantages:

After the casting process and solidification, handling robots remove the castings and transfer them to the finishing department. Turnkey casting cells with all necessary finishing steps are available in robust Mössner quality.

Learn more about our finishing solutions.

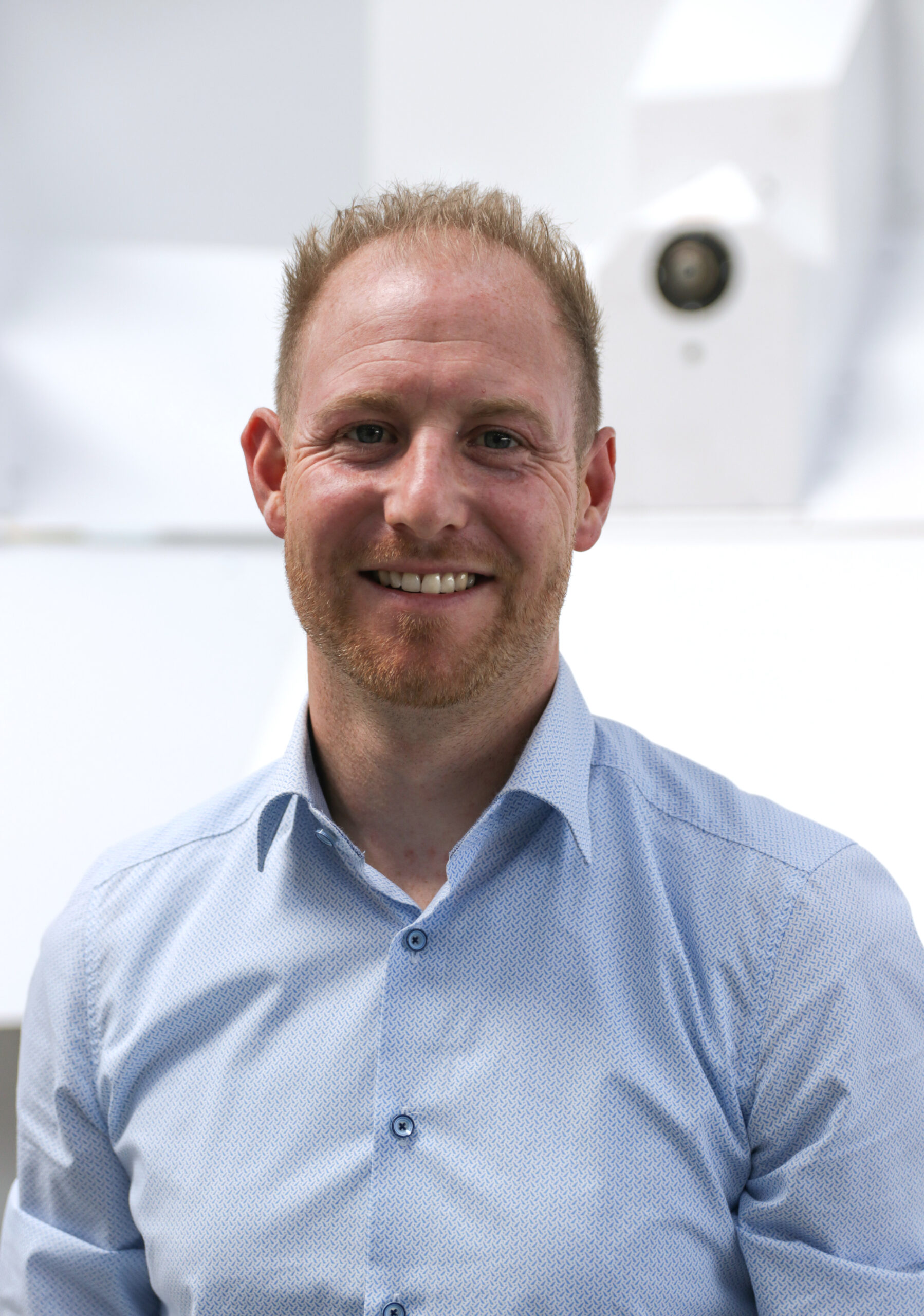

Your contact for Gravity casting