Our cooling systems work with air or water cooling. The air cooling is available for cooling shelfs, cooling towers and cooling tunnels. All systems are available with or without forced cooling. In the field of water cooling, we offer immersion cooling basins with individual cooling water managements, component-specific workpiece holders and lowering units.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Our cooling shelves are available with or without forced cooling. Forced cooling is provided by fans that generate a flow along the surface of the workpiece which leads to cooling of the casting. Additional nozzles for a defined flow can also be integrated. The cooling shelves are designed based on the required minimum cooling times. We adapt the size and design of the cooling shelves exactly to your needs.

The following arrangements are available:

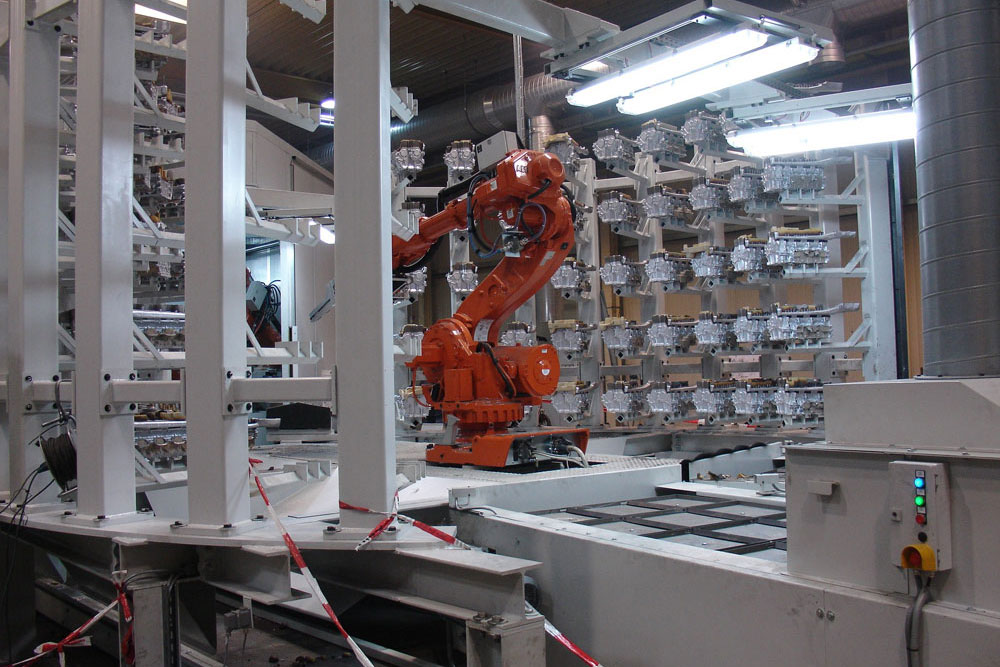

The cooling shelves are arranged in a circle around a robot. The robot automatically loads and unloads the cooling shelves.

Parallel to the 7th axis of the robot, shelfs can be arranged on both sides at different heights or on one level.

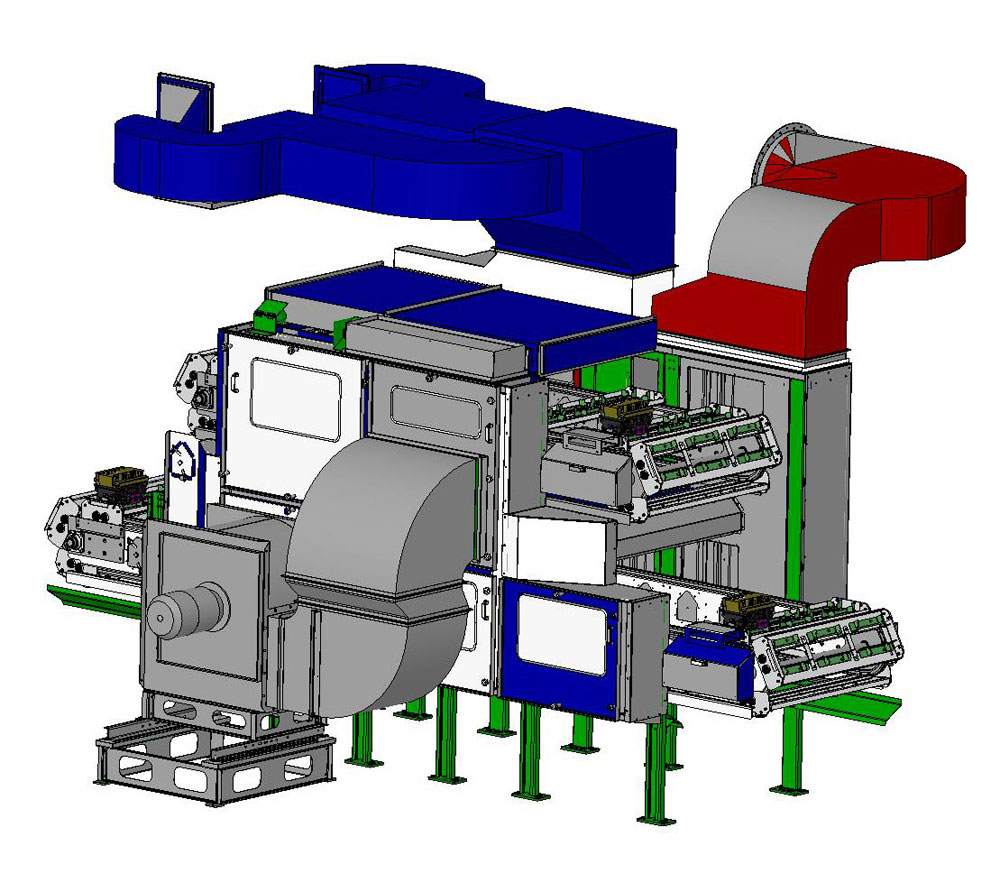

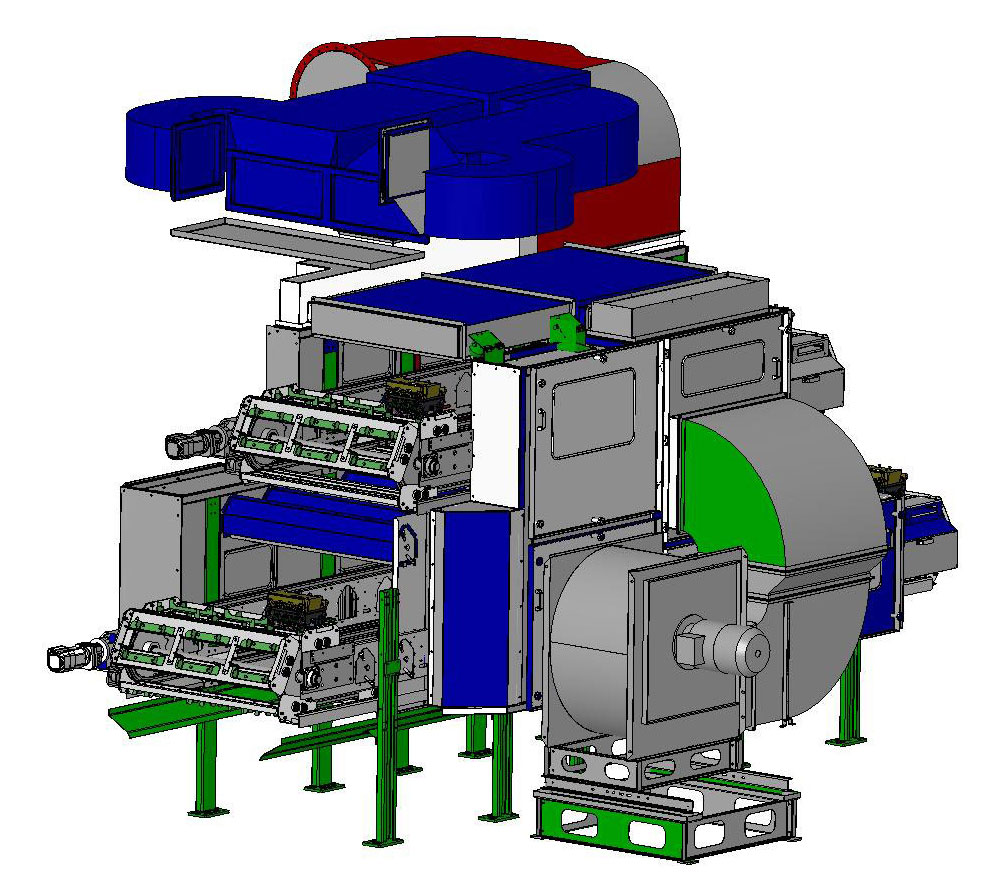

Cooling tunnels allow the castings to cool down as they pass through. The cooling tunnel serves as transfer between casting and processing area. An industrial robot takes over the loading of the cooling tunnel. Optionally, it is possible to strip the sand core before loading. The cooling tunnel is also unloaded by a robot. This robot then loads and unloads the subsequent processes such as decoring, sawing or marking.

Cooling towers based on the paternoster principle represent a space-saving solution. Loading and unloading by the same robot is possible with this type of cooler.

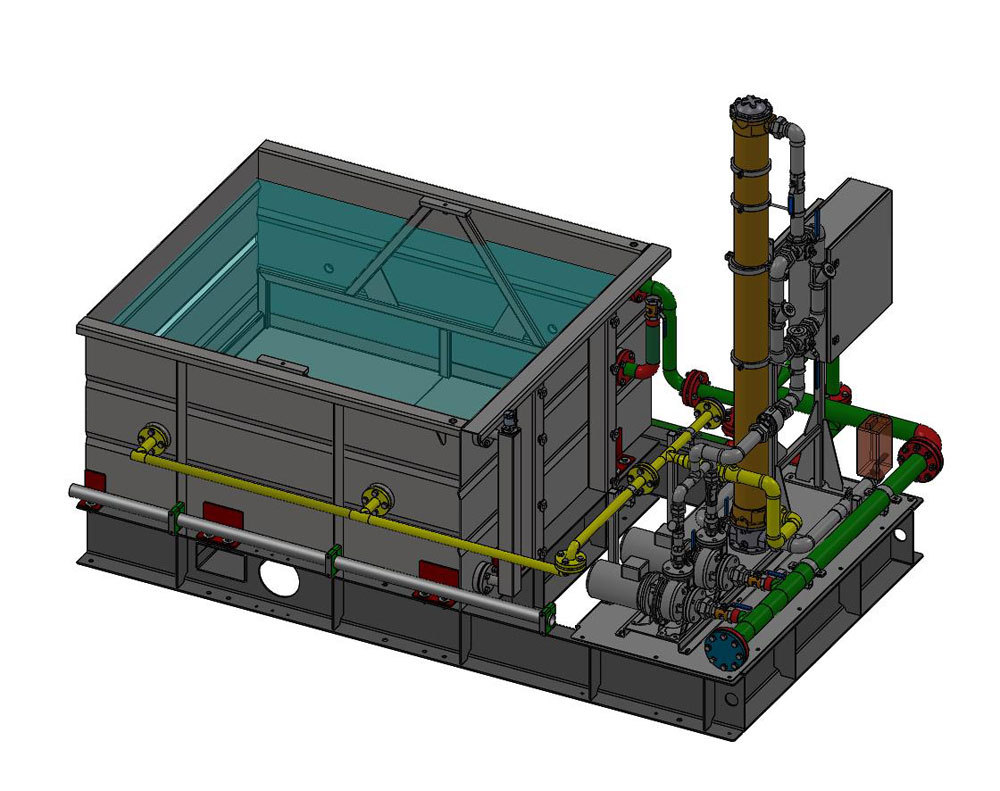

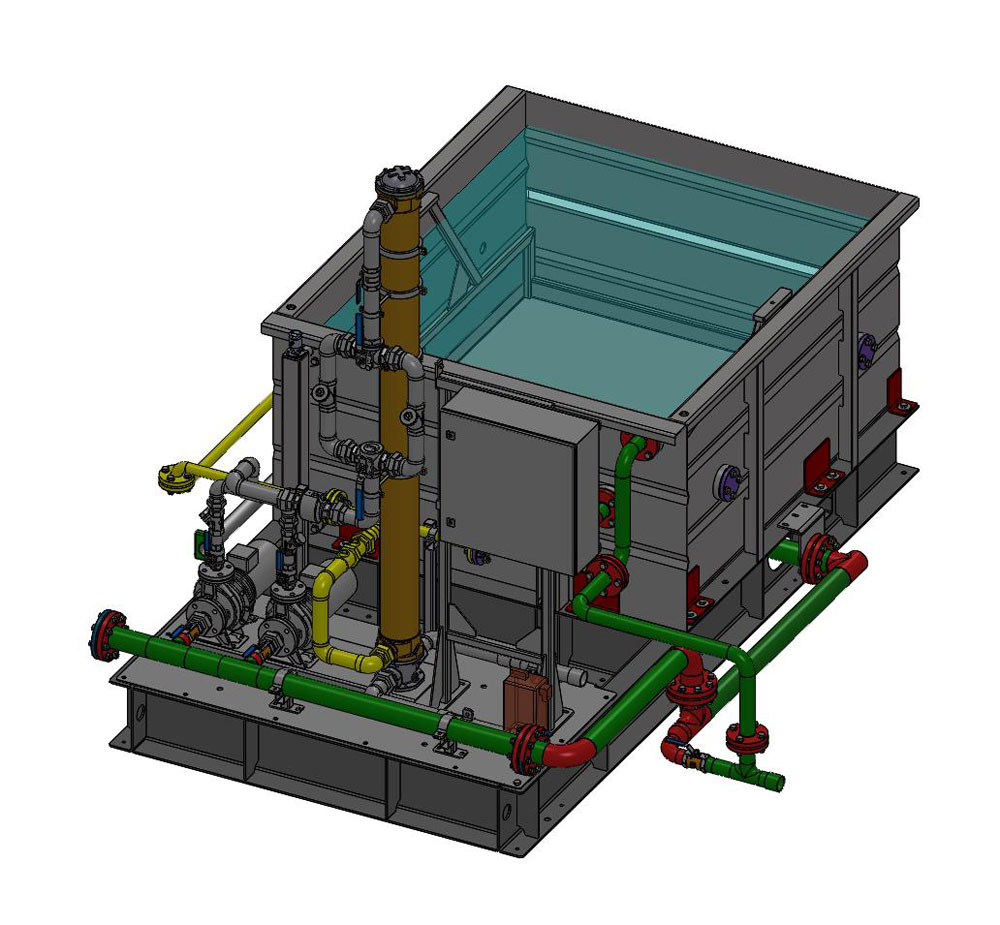

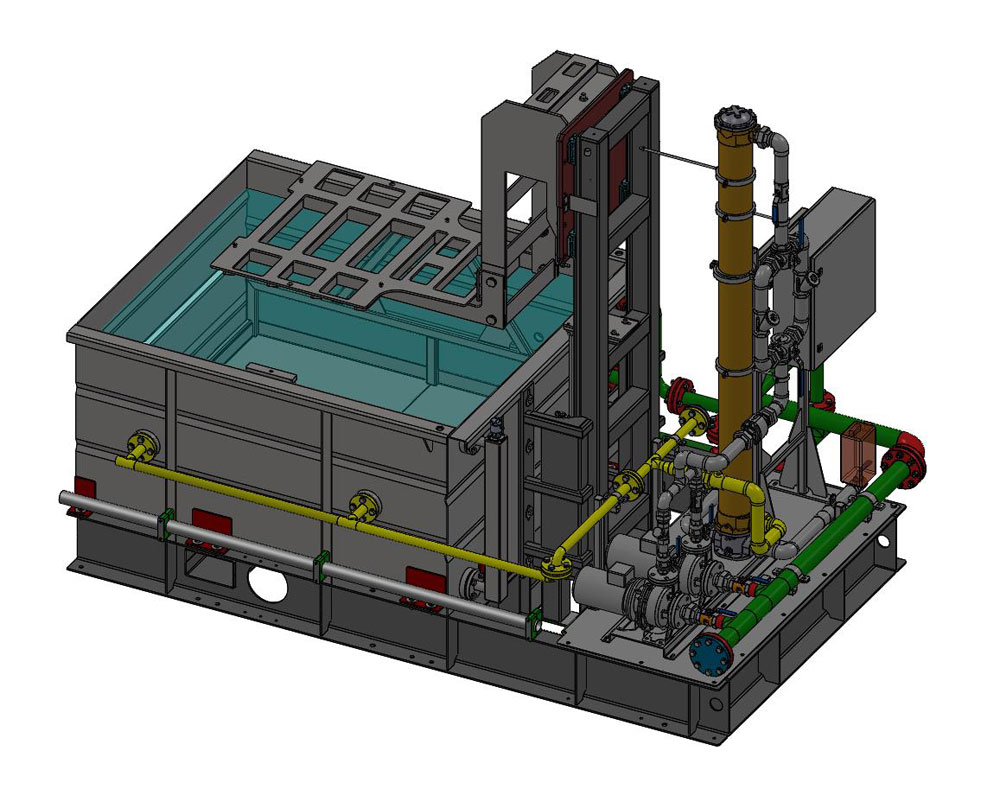

Cooling systems with water cooling are available from us as so-called immersion cooling basins. Our immersion cooling basins are made of stainless steel and are extremely robust. Depending on customer requirements, they have various functions and equipment:

RoboCool is an immersion cooling basin, which is mostly used in die-casting. The hot casting is dipped and swivelled into the cooling basin by the robot. Different temperature controls can be used depending on requirements. A screen basket ensures easy cleaning of the basin.

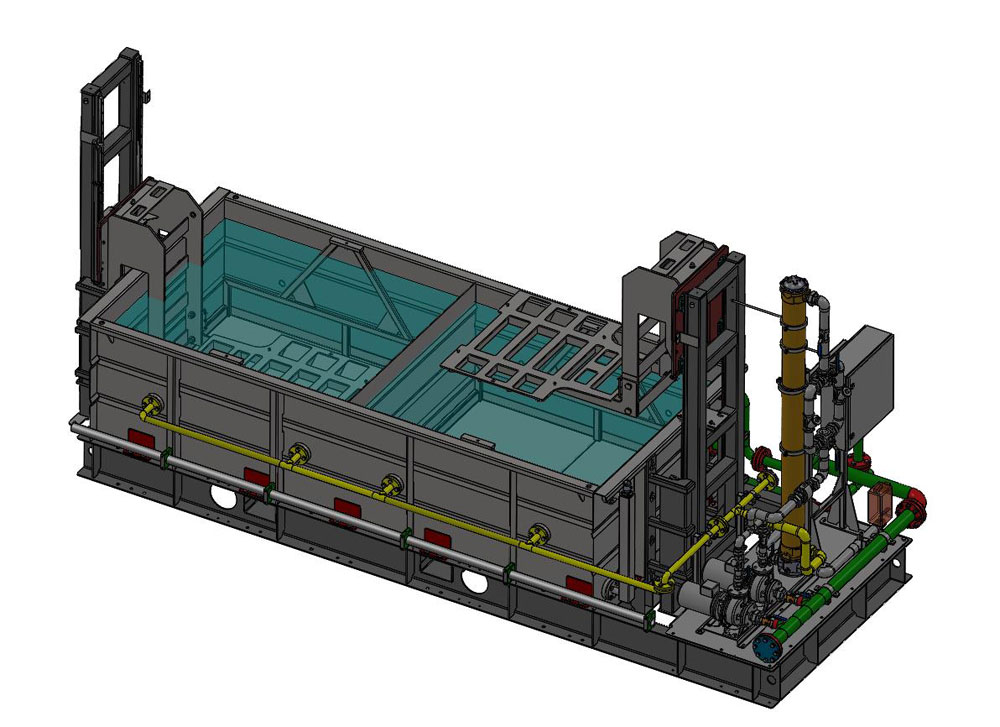

The compact SingleCool immersion cooling basin is equipped with a lowering unit. The advantage of this system is its small space requirement.

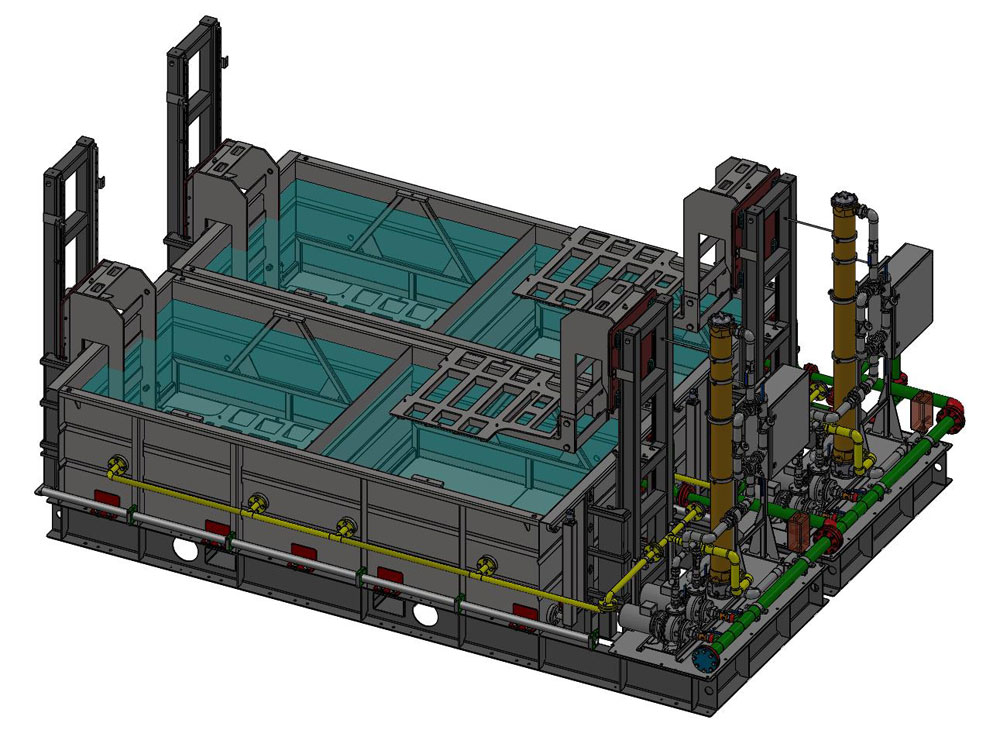

In addition to its enormous capacity, the TwoCool cooling basin has two independent lowering units. This means that a cooled package (e.g. with eight workpieces each) is always available for the subsequent process steps. Redundant circulating pumps ensure controlled and fail-safe cooling.

FourCool is our largest cooling basin. It offers four storage places and lowering units for hot castings. The system is designed for two casting machines and two finishing lines. Its compact design reduces space requirements to a minimum while maintaining an extremely high capacity.

Your contact for cooling