Our new Steel and metall bandsaw machine Mössner REKORD brochures are available.

The prices are valid from July 1st 2020 until June 30th 2021.

You can download the files here: Downlaods.

Our team is ready to give advice on your particular demands- please do not hesitate to contact us!

Your contact for your inquiries:

Mrs. Ingrid Quintin

On the 18th of November Fagor Ederlan held the official opening event of its new plant in the city of Bergara, a small city between Bilbao and San Sebastian, dedicated to the production of aluminium parts for the automotive sector. This region is located in the Basque Country and has the highest density of industry in Spain, where specifically the foundry sector, is one of the main traditional part of its economy.

Fagor Ederlan was honored by the visit of the Minister of the Basque Country, Mr. Urkullu, who pointed out the values of the company, especially in the current international economic situation and encouraged all to believe in the vision of its parent company Cooperativa Mondragon (MCC).

MCC is composed of many co-operative companies grouped basically into four areas: industry, finance, retail and knowledge. In each company, the co-op members (averaging up to 85% of all workers) collectively own and direct the group. An annual general assembly takes place where the workers choose the managing board and have the power to make all the strategic decisions of the group.

The total investment for the new plant was 55 Mio € and 220 people are employed. The capacity of the new plant is 1.7 Mio parts. The total capacity of the group is more than 6 Mio castings a year.

Five lines from August Mössner are already in full production of aluminium knuckles. The project was a big challenge because of the extremely demanding cycle times, but the results and the almost free of failure performance of the lines makes the production management of the plant extremely satisfied with the company August Mössner.

The scope of supply of Mössner covers the five lines of pre-machining, each of them with three robots for several tasks like: taking the parts from the casting machine, cooling the parts in a water basin, laser marking, deburring and sawing.

August Mössner says thank you for the great cooperation and looks forward to many more exciting projects with Fagor Ederlan.

The last years have been characterised by growth, technological innovations and the competition for good personnel. We took advantage of our opportunities and created a good position for the future. This can only be achieved together with the customers – our customers. Teamwork creates top performances, which alone would not be possible. Of course, this also applies to our employees, who are another important reason for our development. The turn of the year is a good time to say thank you once again – to our customers and our employees. Now the pace in the market seems to have slowed down a little. Or maybe not? We are still well on our way, but for us this is all the more an incentive to give even more and to concentrate even more on our potentials. We will continue to break new ground and remain a value-oriented company – especially in view of dynamic digitalization and intensified competition.

A matter that is also dear to our hearts: In recent months, we have done everything in our power to ensure that we can call ourselves a climate-neutral company in the New Year. A big step for us and at least a small step for the environment. We are looking forward to what is yet to come and are full of optimism. Best wishes for Christmas, the New Year and a good start for the next projects.

Standstill is not an option in times of turbulence. That is why our service has more than one dimension. And it offers more than one solution. It offers competent employees, various ways of action and the latest technology. All with one goal: to make sure it works for you. We take care of the topics: machine inspections, maintenance, repairs and spare parts. And we keep asking ourselves the question: What else can we do for you? As there is much that we can do – and there is a lot that takes you further. This includes, for example, our new Augmented Support App. With this app and the use of data glasses and tablets, we can analyse problems at the customer’s site more quickly and solve them together with the contact person. In addition, information and documents can be easily read on the machine via a QR code. There is no need to search for the corresponding documentation and the important information is quickly available. Furthermore, the documents and information made available via cloud are always up to date. There is no need to update and handle the documents for the customer. Further advantages of the app are the possibility of support by live video and thus also the cost-efficient, prompt support by additional, possibly also external experts. Our ability to act quickly and easily is always aimed at increasing the productivity and availability of your equipment and reducing downtimes. Have we sparked your interest? Then we look forward to hearing from you.

Contact person for machine inspections, maintenance and repairs

Mr. Mario Kreisel

Telephone +49 (0)7175/99806–44

Your contact persons for augmented support

Michael Munz

Telephone +49 (0)7175/99806–11

Simon Lojewski

Telephone +49 (0)7175/99806–82

Your contact persons for spare parts sales

Ms. Simone Markowetz

Telephone +49 (0)7175/99806– 43

Ms.Tatjana Tietze

Telephone +49 (0)7175/99806–64

As well in this year, it has been shown again, that the GIFA is the most important international industry event in the field of casting. And it is important to be present and to be interested.

We have again maintained exciting customer contacts and had the opportunity to look over one’s shoulders and exchange experience. We are convinced that competition revives the business.

First implementations are ready for the market. But there is still much to do. Our applications, such as augmented support and remote support, were met with great interest among many trade fair visitors, as well as our app, which shows not only our commitment but also our doer qualities. But of course it continues.

After the GIFA we now concentrate on implementing new solutions for our customers. With Mössner analytics we now offer a digital platform for capturing, processing, saving, visualising and analysing machine data. This analysis tool significantly increases the transparency of the behaviour, the consumption, the production data and the condition of a plant. The resulting data is the basis to create suggestions for upcoming maintenance and thus to provide spare parts on time. Are you interested, does demand exist? We give non-binding advice to quickly inform you of where we can be of support.

Looking back – the year 2018 was again very versatile, exciting and challenging. Despite much insecurity in the markets, we were successful throughout the whole year, due to the overall good economy and innovative products.

For this, we would also like to thank you!

We have always liked working close to our customers, to be able to develop individual, efficient solutions. And again, this will be our intentions and challenges for the New Year 2019.

That was 2018: more manpower and new market presence

We owe our success to the requirements of our customers and to our aspiration to not only develop individual engineering solutions, but also increasingly integrated concepts. This is where we have clearly and successfully grown. That is why the number of our employees has increased – and we were able to expand our capabilities with the increasing manpower and targeted further training measures.

Our subsidiary in China – which was established at the beginning of the year – is also making excellent progress. We see great potential in this market, and through the projects on site, we gain important experience.

Interesting and successful was also the Aluminium 2018 in Düsseldorf, at which we were represented with our own booth. This small and specialized exhibition has shown – something that is worldwide increasingly being revealed as important: digitalisation of work processes.

What the New Year will bring…

You will certainly hear of one or another innovation from us. Especially industry 4.0 and the meaning of digitalisation are decisive subjects, this will also continue in 2019. There will be much to see at the GIFA 2019 in Düsseldorf from June 25th to 29th.

Of course from us too! We will keep you updated.

We wish you a wonderful and successful year 2019!

Our new Steel and metall bandsaw machine Mössner REKORD brochures are available.

The prices are valid from July 1st 2018 until June 30th 2019.

You can download the files here: Downlaods.

Our team is ready to give advice on your particular demands- please do not hesitate to contact us!

Your contact for your inquiries:

Mrs. Ingrid Quintin

At the special purpose machinery manufacturer Mössner, six prospective technicians are engaged with the subject Industry 4.0 and the progress in the range of 3D prints of metals. Currently, they are trained to become certified technicians at the technician school in Aalen. Training takes 2 years in full time. In the second year they write their degree theses. For this, the six technicians meet once a week at Mössner in Eschach, where the necessary hardware, design and programming software are provided. The technicians in the field of electrical engineering and mechatronics are engaged in the subject Industry 4.0. The prospective electrical engineers are involved with the modernisation – the so called retrofit – of an existing test bandsaw at Mössner. This bandsaw is to be made fit for the topic Industry 4.0 and also serves as a pilot system later on. Especially the subjects networking and visibility present a key project requirement of the technicians. In the new system concept all sensors and actuators are linked together with bus systems. Furthermore, the energy consumption of the system is recorded. The purpose of the newly gained data is to recognize coherences, create forecasts and enable self-optimizations of systems in the future.

The area of responsibility of the mechatronics includes the design and development of a robot cell. Equipped with an ABB robot and the newest automation technology this robot cell is intended to be a training system for robot programmers as well as for research purposes for the subject Industry 4.0 and digital twin. The digital twin is a virtual system model, which is completely identical with the real system. In the future it is plant to virtually put the special purpose machinery into operation with the assistance of the virtual twin. Hereby the commissioning time is to be reduced and possible mistakes in the development process detected. A further central subject is the interlinking of a robot cell. Integrated in the company’s network, all important functions can be controlled via a computer workstation or mobile devices, such as tablets or smart phones. The system is also interlinked with the internet. A remote maintenance concept enables Mösser to access the complete system, read relevant process parameters and the live streaming of a network camera. As a result, reaction period and travel time can be minimized.

The technicians in the field of machine technology concentrate on 3D printing. 3D printing of metals requires the separation of the workpiece from the so called building platform after printing. For this, Mössner’s precise band saws represent an alternative to cost-intensive wire cutting. Based on customer requirements, which were determined by the technicians, a fixture was developed, which can be integrated in Mössner’s band saws. Further important parts of the task were the calculation of production parts, cost management and an ergonomic design of the fixture for the system operator. After completion of their training, three of the six technicians will be hired by Mössner to work in the fields of software development of robot systems, mechanical design and research and development.

All technical theses were publically presented on June 29th at the technician school in Aalen.

The group photo shows (from left to right): Christian Kunz und Stefan Hieber (supervisors of prospective technicians), Sebastian Haas, Hannes Hilbert, Florian Rehle, Florian Windschüttl, Martin Angstenberger und Christoph Ziebart.

Being close to our customers is one of our strengths. We are – where we are needed. Right at the place, where we can carry out the tasks directly, placed by market and customers.

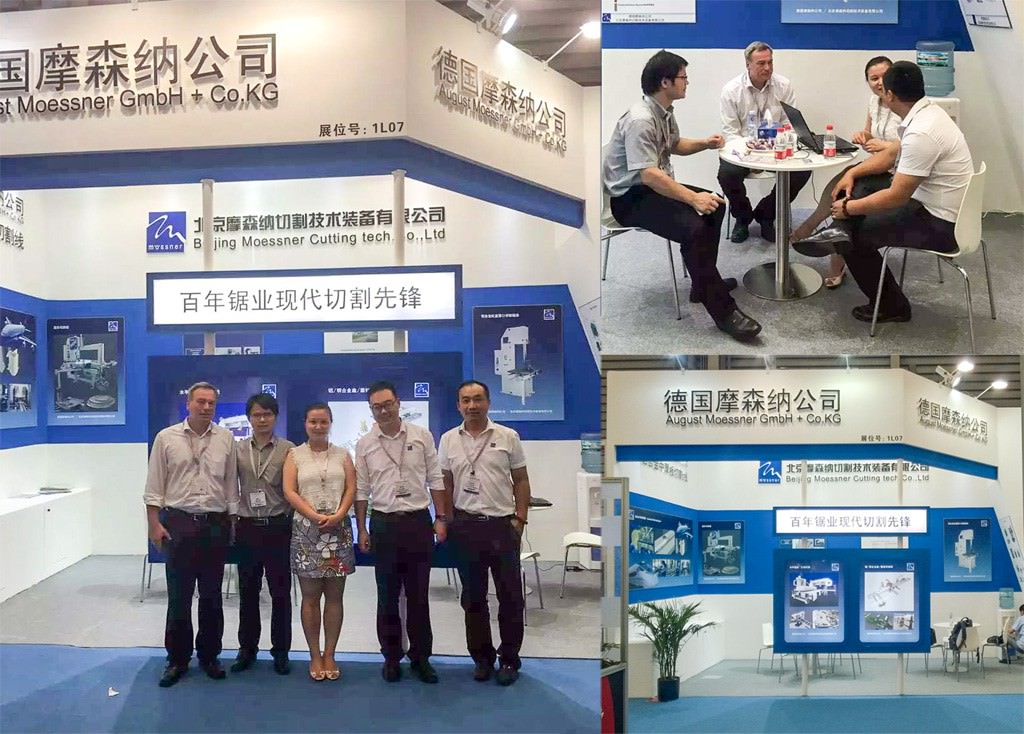

As seen by us from Eschach, for this, we even work at the other end of the world: in China. Since March of 2018 we are in Kunshan, a city near Shanghai, on the spot – with our subsidiary “Mössner Automation Technology Co. Ltd.” On-site service is provided by our sales representative Mr. Edison Zhou.

Brigitte Hartmann – based in Eschach – is assigned manager of the subsidiary. With her long-time experience, Brigitte Hartmann is a proven China expert.

With our subsidiary we strengthen our service capabilities and activities in China. Our know-how, combined with the continuing presence on one the most dynamic markets of the world, underlines our sustainable service standards.

We look forward to an exciting time and the new challenge!

Please feel free to contact us for further information.

The “street of professions” initiated by the knowledge workshop Eule and based in Schwäbisch Gmünd, entered its fifth round on April 4th 2018. Each year, students in 8th grade and up have the possibility to receive an in-depth view of training professions and professional fields. This event is a great opportunity to receive further information about participating companies and their training professions.

Mössner was onsite with its training cell for robotics and control technology. With an operator panel a small industrial robot could be guided along the “hot wire”. Supervised by Christian Kunz, director of R&D and Ferdinand Klaus, a student at Mössner, studying electrical engineering / automation in a dual study course, the students received first impressions in robotics and control technology. A further highlight was Mössner’s virtual reality glasses, which enable a virtual view of a production line. Alongside, lively discussions about training and study possibilities at Mössner took place.

On March 16th 2018 the “Gmünder Training Night” took place at the Congress Centrum Stadtgarten in Schwäbisch Gmünd. This fair is a possibility for prospective school graduates to receive extensive information of companies and their training opportunities, before choosing a career.

On this occasion, Mössner presented its small robot, which visitors could not only examine but also operate themselves. With an operator panel the robot arm is guided along the “hot wire”. With little skills and a steady hand visitors were able to guide the robot gripper along the wire in form of a loop. The orange signal lamp, which visually indicates contact with the wire lit thereby only on rare occasions. Afterwards, the participants were rewarded with a present from the Mössner treasure chest.

A heartfelt thanks goes out to all the visitors for stopping by at our booth and for the many good and inspiring discussions.

The Educational Fair East Württemberg took place at the vocational school in Aalen on February 24th 2018. We were onsite again this year and exchanged information with many interested visitors.

Mössner offers vocational training for the professions: industrial, machining and electronics technicians. Field of duties are planning and project engineering, concrete implementation, building and commissioning of special machinery onsite – an exciting challenge with every new project.

Mössner based in Eschach has become one of the leading manufacturers of complex special machinery for sawing, milling and inspection operations. A widest variety of customers worldwide – e.g. in the automotive industry – inquire about this special machinery. Therefore, the vocational training positions Mössner offers are also special in regard of diversity, challenge and future orientation. “The good quality of our training is ensured by closely interlinking theoretical knowledge and practical implementation. Something we put great emphasis on from the beginning. Approaching actual tasks with correct knowledge and knowhow is fun and motivating, we notice this time and again, no matter which profession our trainees have chosen,” says one of Mössner’s training supervisors Rainer Schneider. “As a result, self-confidence and self-responsibility are practically automatically promoted, not only the trainees profit from this but also the company – this is one of the secrets of success.

The enormous development of our company would not be possible without targeted intensive trainee promotion”, says General Manager Franz Sachsenmaier.

With virtual reality glasses, visitors had the opportunity to virtually dive into a processing cell for castings to fully observe the inner life of this cell.

We thank all the visitors for stopping by!

An exciting year came to an end and we like to contact you once more to personally say thank you. Thank you for the good co-operation, trust and the successfully implemented mutual projects.

The past months are a very good starting point for the next year. As plant, we have designed and delivered a large amount of systems for the processing of chassis and structure parts promptly. Our newest horizontal bandsaws, for the processing of aluminium, also continue to provide an excellent order situation. Furthermore, our new additional assembly hall has been put in operation.

Of particular importance to us is the continuing education and junior recruitment, which we have promoted – also in this year – by co-operating with technical universities and by exhibition presentations.

These are just a few beautiful moments from an exciting year of business, some of which we have experienced together with you. That shall be the same in the new year.

Together with you and our staff, we would like to take further important steps towards a prosperous future.

Wishing you days filled with peace and nice experiences and of course – a good start into the new year.

On a sunny Sunday, October first 2017, the new assembly hall and new offices were officially inaugurated at August Mössner GmbH + Co. KG. Employees and their family members celebrated the occasion together with the citizens of Eschach. Managing Director Franz Sachsenmaier opened the event with a speech describing the decisions and steps during the construction phase. The starting signal was set off in late autumn of 2016. After that, the planning activities began. Already in February the construction plans were handed over to the community for the examination procedure. The new offices were designed by architect Martin Förster, a resident of Eschach. Together with Mössner’s purchasing manager Markus Fuchs, public tendering and construction supervision took place. On March 8th 2017 the excavations began and on August 21st 2017 the assembly hall and the new offices were ready for occupation.

The new hall offers further 2.100 square meters for the assembly of large machines. Furthermore, additional 440 square meters office space was created, in which the research & development department as well as SPS and robot programmers moved into.

Franz Sachsenmaier thanked the involved building contractors for their cooperative partnership, with which the remarkably short construction period could be achieved. Further gratitude was expressed to the Eschach community, especially to Mayor Jochen König, for the continuous support during the construction phase. Following the speech, the guests had the opportunity to visit the new assembly hall and offices, with their various attractions, such as virtual reality glasses, which enabled visitors to immerge into a 3D-world and virtually walk through a Mössner production line.

Kid’s fun was provided by a jumping castle, glitter tattoos and a balloon artist, who created a wide range of colourful balloon figures.

Catering was provided by Imbiss Irtenkauf. The guests were musically entertained by DJ Indi and the Musikverein Holzhausen.

A heartfelt gratitude goes out to our partners, who contributed to this beautiful Event.

Our new Steel and metall bandsaw machine Mössner REKORD brochures are available.

The prices are valid from July 1st 2017 until June 30th 2018.

You can download the files here: Downlaods.

Our team is ready to give advice on your particular demands- please do not hesitate to contact us!

Your contact for your inquiries:

Mrs. Simone Hieber

Company Moessner is part of the 1st Casting Workshops in Mexico 2017 organized by our partner Kurtz GmbH.

Take the change and join the conference at Querétaro and Monterrey.

“You will get a great take-home value with many new ideas for improving your efficiency in the production of complex cast parts for the automotive sector.

Our successful partnership stands for technological lead and reliability and offers huge productivity increases while ensuring perfect quality.”

Dates:

Querétaro: Monday May 15 to Tuesday May 16, 2017

Monterrey: Thursday May 18 to Friday May 19, 2017

Locations:

Querétaro: DoubleTree by Hilton Hotel Quéretaro

Monterrey: Holiday Inn Monterrey Valle

Who should attend?

Management and employees from R&D, planning and purchasing in the automotive sector

We are looking forward to the next event – this time in Mexico!

Details and RSVP: workshop-mexico.kurtzersa.com

Please register and book your stay until April 21, 2017!

Questions to the workshop?

Please do not hesitate to contact:

General Requests:

Ms. Vanessa Ibarra (Spanish) |

Phone +52 1 33 1116-7900

An eventful year came to an end – the perfect moment to look back, to briefly review and to look towards the future.

What happened? Again – 2016 we developed, produced and delivered innovative systems in the range of Unfinished Casting Machining and Aluminum Technology. Together with our customers the systems were set up, started up and adjusted in accordance to locations and respective requirements. As, for example in Mexico, the USA and China.

Many thanks for your trust!

With our know-how and high quality products, we were able to contribute in part to the success of our customers. Worldwide. For the trust – once again – we would like to take the opportunity to express our heartfelt thanks to our customers, partners and staff.

Currently, we are already working on exciting new contracts and projects and we are looking forward to implement them together with you.

In this spirit – we wish you a good start into the New Year 2017.

From November 29th until Dezember 1st the ALUMNIUM in Düsseldorf took place under the motto “Visions become reality”. More than 1000 exhibitors from more than 100 countries presented visitors with insights from producing and processing aluminum industry. With bandsaws for bars, billets and T-bars as well as bandsaws for the production of plates from blocks Mössner covers the entire topic profile of the trade fair perfectly. The focus lies specifically on optimal and targeted solutions, with which processes can be profitably optimized. Our experts were able to inform the interested visitors extensively about the newest efficient and economical technologies. Sales manager Brigitte Hartmann expressed her satisfaction at the end of the exhibition: “the high-quality conversations and the resulting inquiries enable us furthermore to start highly positive into the forthcoming year!”

Mössner warmly thanks all the customers, suppliers and visitors for their visit. We are glad you took the time for a conversation about our products at our stand.

In 2016 Mössner was furthermore represented at the AIM held at Aalen University. Besides establishing many interesting contacts to students and lecturers, the Mössner Team – Christina Necker, Christian Kunz and Stefan Hieber – informed about internship semesters, student degree theses and entry opportunities at Mössner.

Within the course of lectures to the subject “Hidden Champions” Christina Necker and Christian Kunz introduced Mössner in detail. Thereby they provided access to the 118 years of company history and presented just why Mössner is one of the global leaders of bandsaws for slabs, plates and blocks.

Mössner thanks the many visitors and looks forward to next year!

This summer Mössner offered a children holiday program for the children their employees.

It started in August with the in-house event “to program with Arduino”. The research and development department; under the direction of Christian Kunz; had created an exciting program for the children. Under the guidance of Eric Hinderer, student trainee at Mössner, the children screwed and programmed with ARDUINO.

ARDUINO consists of a circuit board with a microcontroller and is a type of mini personal computer. The ARDUINO is programmed with the programming language C++. At the inputs and outputs of the ARDUINO diverse electronic components can be connected to. In course of the holiday program the basics of ARDUINO programming were introduced. In small projects, various sensors, actuators and LEDs were connected to the ARDUINO and programmed.

The efforts of the young programmers were rewarded and at the end every child had assembled and programmed its own small computer. The participants ended the successful days with ice cream.

From 12th until 14th of July the “Aluminium China” exhibition took place in Shanghai at the New International Expo Centre. Many interesting conversations were held.

Hans Kunz, the production manager retires after 25-years of employment at Mössner. The managing director Franz Sachsenmaier, the workers council and the employees congratulated Hans Kunz and wished him all the best for his future.

From 17th until 20th of May Mössner presented a decoring machine, a milling spindle for deburring of castings and a bandsaw machine in Beijing, China.

From a decoring box which can do almost everything to our new robot deburring cell for tailored workshop programming and the possibilities of our new deburring centre: the presentation of our innovations for the processing of cast parts at GIFA 2015 in Düsseldorf, Germany was a complete success. Thanks to everyone who visited us.