Simulation technology enables early fault detection in the development phase. We take care of the simulation of the plant and the robot solution for you. As a result, the plant concept, the process simulation as well as the offline program of the robot path movements are available to you, according to the scope of simulation.

Robot simulation

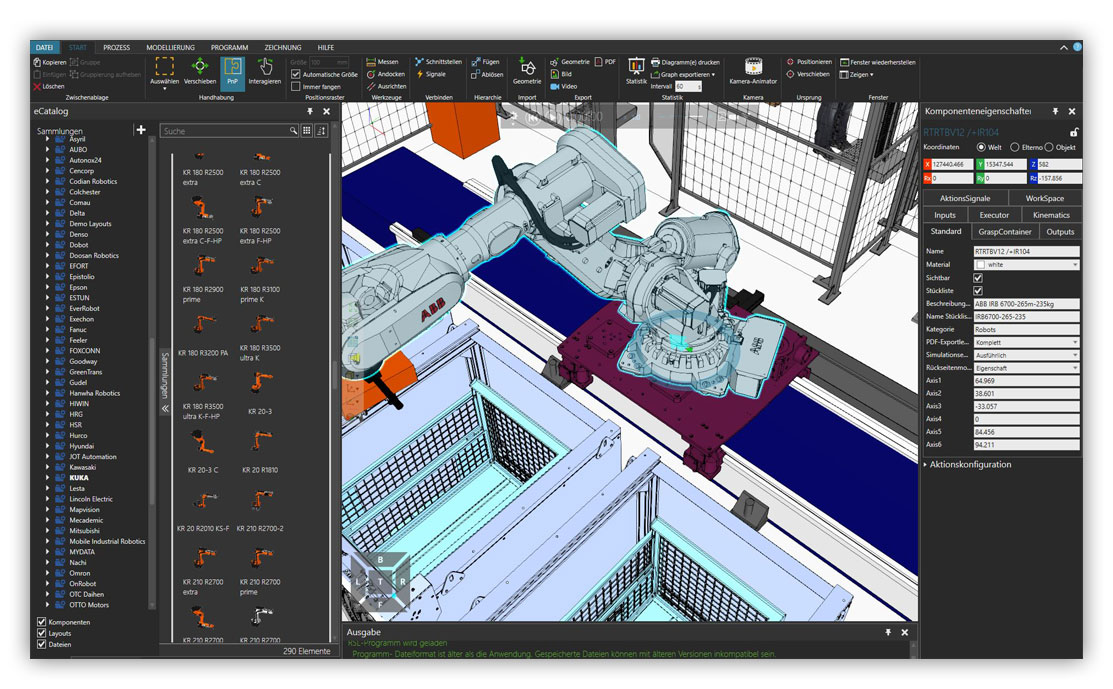

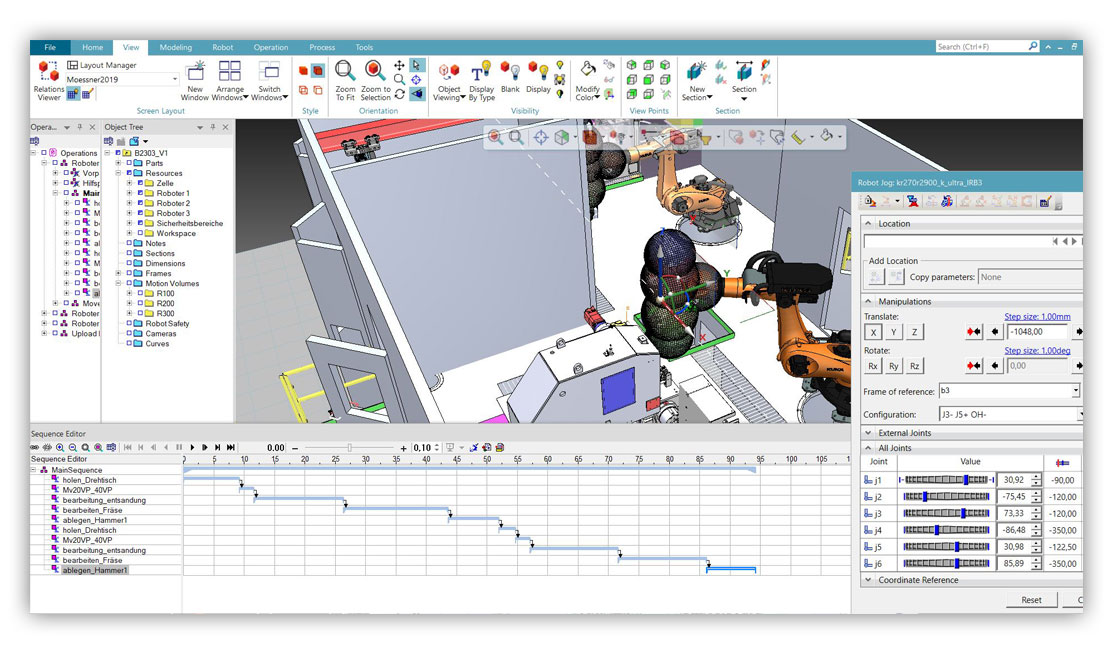

Through concept studies, we define the type of robot necessary for your requirements or check the suitability of kinematics proposed by you. In addition to determining the required reach, positioning and base height of the robot, the load capacity is calculated. The simulation model of your plant is created by using 3D CAD data. This enables us to check any collisions that may occur and make recommendations for the optimum positioning of the individual plant stations and robots. During the simulation, not only collisions are avoided, but also movements and positions that lead through the singularity.

Direct, rapid feedback is important in order to drive optimisations forward as early as the concept phase. Therefore, in addition to the 2D layout of the plant, we provide you with a process simulation video at an early stage.

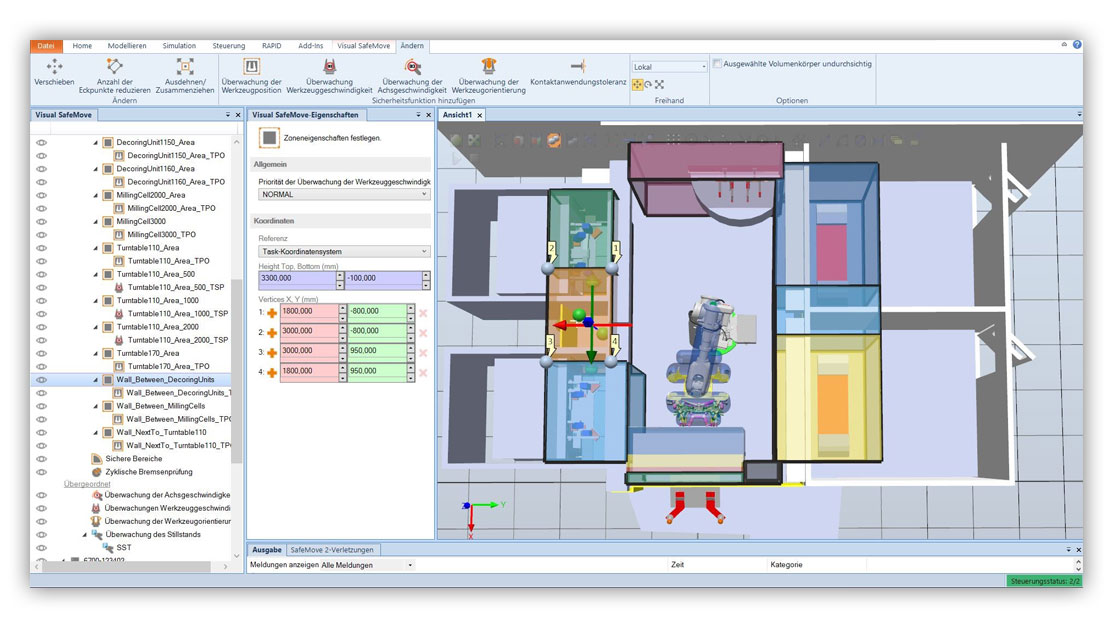

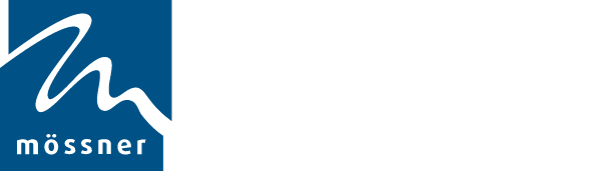

The motion sequences of your ABB, KUKA or Fanuc robot are created using offline programming tools. The resulting source code can be used for the actual robot. Envelopes can also be calculated and the safety areas for SafeOperation, DCS and SafeMove Pro can be defined. Virtual commissioning of the robot considerably reduces the commissioning time for new installations. When converting or retrofitting existing production plants, downtime is reduced to a minimum. The collision analysis using simulation technology enables the rapid implementation of robot integration.

We offer cycle time analysis and cycle time optimisations for new and existing plants. By using RCS modules (Realistic Controller Simulation) the cycle time of the robot is examined in the simulation and potential savings are shown. The cycle time analysis is up to 98% accurate. For the cycle time evaluation, the existing code from the robot is transmitted into the simulation, then the optimised code is returned to the robot – the implementation time is therefore short.

Advantages

Applied software tools