Like the other Mössner band saws, the SSF 801 can be used universally and is capable of handling even the “heaviest” sawing tasks. Band saw blade dimensions from 13 to 34 mm are possible.

| Technical specifications |

SSF 801 |

|---|---|

| Voltage | 400 Volt/50 Hertz |

| (other voltage against extra cost) | |

| Cutting speed range transmission | 26 – 180 und 290 – 2000 m/min |

| Cutting speed range flange bearing | 500 – 2000 m/min |

| Wheel diameter | 800 mm |

| Table size | 960 × 1000 mm |

| Table height | 1130 mm |

| Max. table payload | 750 kg |

| Cutting width | 785 mm |

| Cutting height | 670 mm |

| Motor power | 11 kW 400/690/50 Volt/Hertz 1500 × 1/min |

| Dimensions | 2240 x 1080 x 2900 mm (L x W x H) |

| Net weight approx. | 2300 kg |

Technical details

Optional equipment SSF 801

Butt welder

Butt welder EBS for sawblades, incl. shear and grinding motor.

Available EBS types:

Special voltages for butt welder

Different voltages can be realised depending on the recipient country.

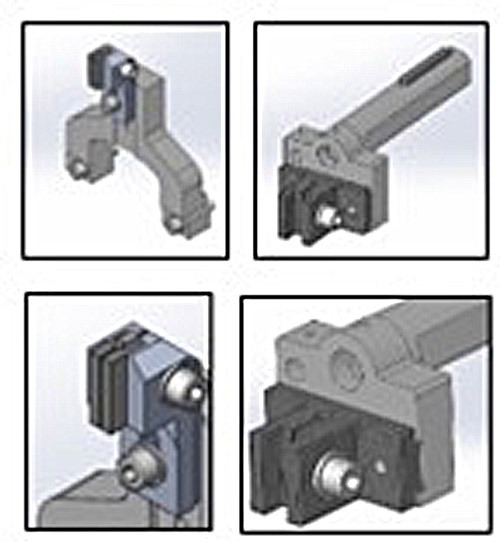

jaw guides with inserts

Bracket jaw guides bottom and top including carbide-tipped guide inserts for bracket jaw guides

Inserts for jaw guides

Carbide-tipped guide inserts for jaw guides

Roller guides

Roller guides inducing guide rollers used for curing speeds starting at 250 m/min.

Guide rollers

1 set = 2 pieces with rim, 2 pieces without rim

Guide dimensions depending on the saw band used

Emergency push-button

Additional foot switch on the lower part of the machine for emergency stop.

Magnetic brake upper wheel

Automatic braking of the upper wheel by magnetic brake, in case of loss of tension or saw blade breakage.

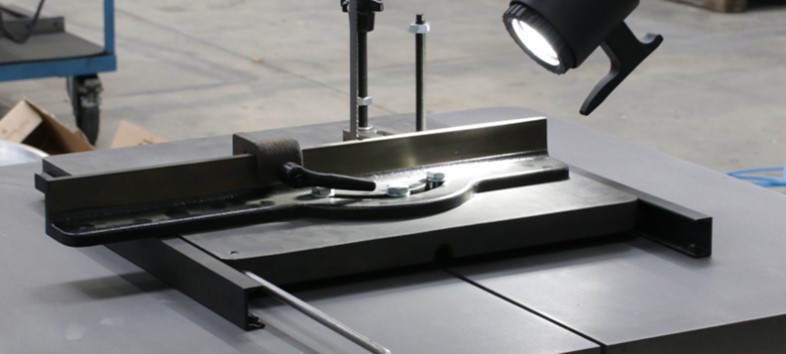

Straight cutting device

(not available with feed table)

The straight cutting device is placed on the worktable with 4 pins. The feed is manual. By means of a mitre-adjustable feed angle and an adjustable cross-cut fence, cuts can be made at an angle of up to 45° and in lengths of up to 230 mm. The cutting depth can also be limited with another adjustable stop.

Technical data:

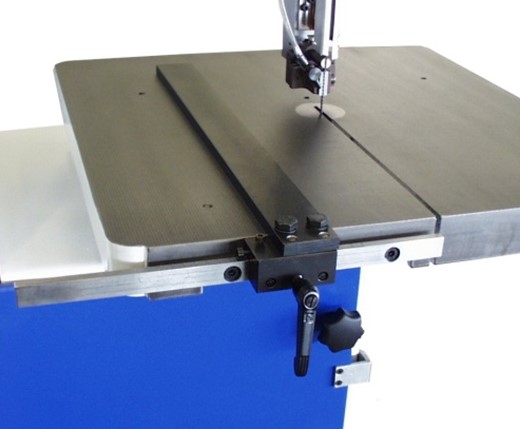

Parallel ledger

Parallel ledder consisting of:

Type SSF 420

up to 290mm

Type SSF 520/SSF 630/SSF 1600

up to 390mm

Type SSF 801

up to 550mm

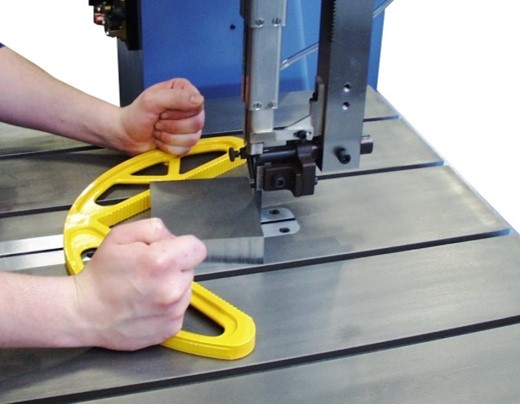

Workpiece holder

Workpiece holder for safe and exact guiding of the workpiece.

Cutting support device

The cutting support device is used to cut thin sheets with thickness up to approx. 6 mm. The small contact surface prevents the sheet from vibrating and thus reduces the risk of saw blade teeth breaking.

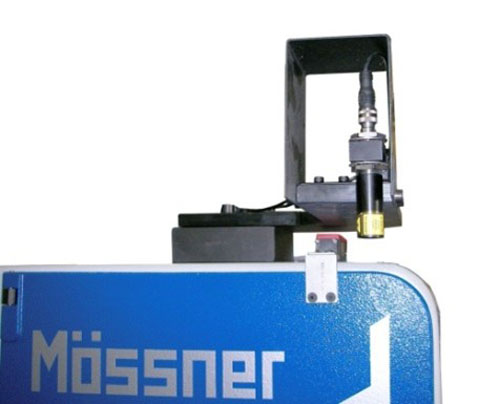

Alignment with laser

For exact positioning a laser beam projects a laser beam on the surface of the workpiece. This beam points out the cutting channel.

Used laser: Helium-neon-laser with a prefixed lineoptic, not dangerous for the eye (corneal reflex).

LED lamp

LED lamp for lighting of the working area.

Feed tables for band saw SSF 801 on request

One-axis-positioning control

The desired feed length is entered via keyboard. The actual value is shown on the digital display. A resolver is used for electronic routing. The feed movement is switched off automatically when the pre-set measurements are reached. A maximum of 10 programs with 10 lines each can be stored.

Minimum spray device

Lubrication of the saw band by a minimum spray device.

Consisting of:

– 1 spray head

– Pressure container for 1 l content

Hydraulic sawblade tension

Blowing off device

Blowing off chips at the sawblade. Pressure air provided by customer.

Connection piece for suction

Suction of chips at two points: lower sawblade guidance and lower wheel-box. Joined to 1 suction point for connection to suction system (by customer).

Design:

Special voltage band saw

adapted to the respective country of destination

Special paint

Swivelling control panel

(included in type SSF 1600)

Control panel with two pivotal points:

The most important operating keys are integrated in the control panel. The main switch remains in the control cabinet. Height of bottom edge operator’s panel 1400 mm.

Suction unit for band saw SSF 801 on request

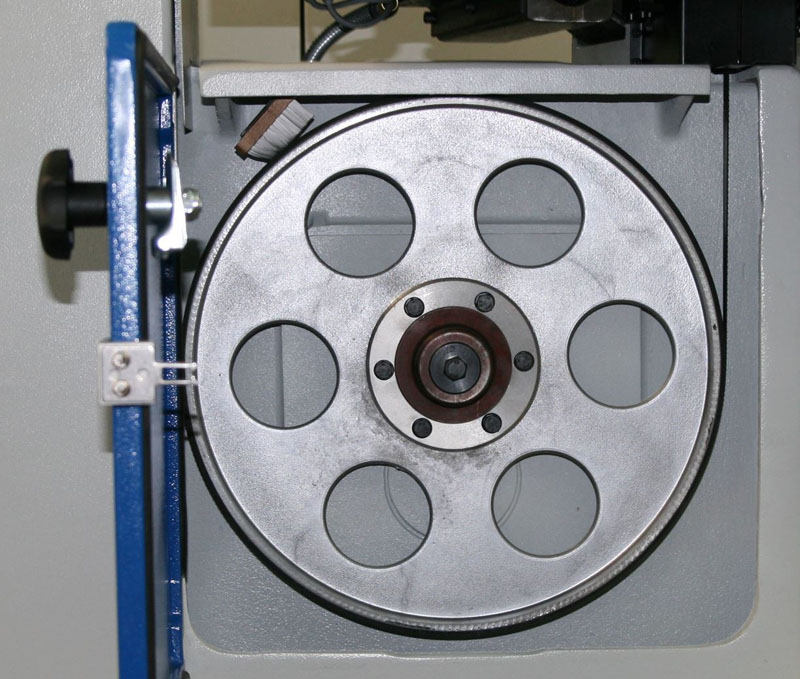

Wheel

Aluminium wheel with vulcanised hard rubber coating

Credit notes are issued for returned used wheels that are in usable condition

Saw bands

We offer you saw bands in a wide range of designs and for varies application areas whether in

Saw band dimensions from 13 – 34 mm are possible. We will be happy to advise you and together we will find the suitable saw band for your application.

Special high-performance lubricant

Our lubricants fulfil all legal framework conditions and ensure a long service life and surface quality. The lubricants are suitable for machining high-strength steel materials, aluminium and AL alloys as well as non-ferrous metals.

Available in different package sizes

Your contact for Mössner bandsaws